Today we worked on the continuity problem we’re having with the finished U2F tokens.

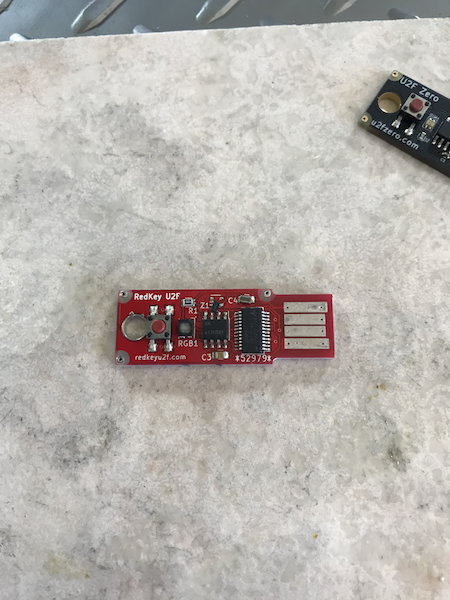

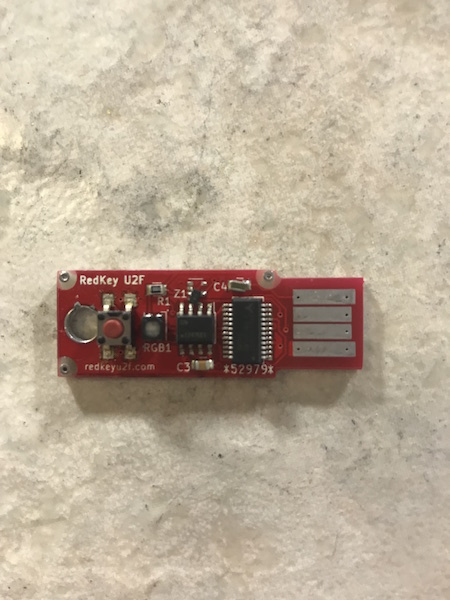

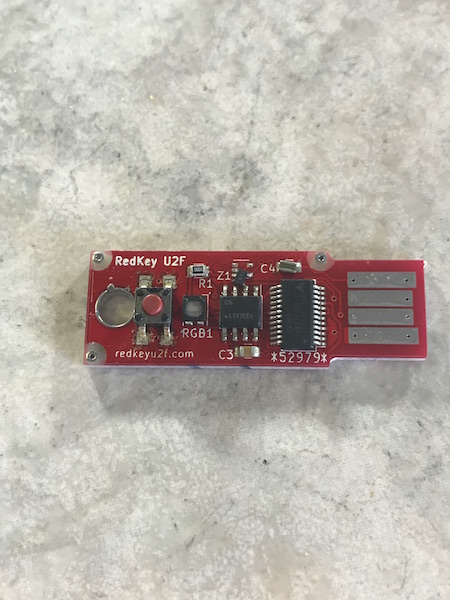

After much discussion and looking at the token’s wire diagrams, it was decided that we should try taking parts out of the circuit to test the continuity. This meant that I had to learn how to desolder surface mount components- a feat much larger than regular desoldering. Just desoldering one component took hours and many different methods. Using soldering wick to suck up the solder worked well, but the leads were still stuck to the pads. A heat gun proves inefficient without a smaller nozzle, and even normal tweezers couldn’t get underneath the small part. Adding and removing solder with flux, and even trying to scrape the solder around the leads off didn’t work! Here’s some pictures of the progress (I was working the switch- the left most component):

Finally, after prying and working the component I managed to get it free. The breaking point was when I managed to find a pair of curved tweezers that were small enough to get under the leads of the component. Then, while I was using the soldering iron to heat up 2 leads at a time, I could wiggle the tweezers…while also trying to hold down the small PCB. Just repeat that on the other side, and bam! A free switch.

After the switch was free, we checked the continuity against the good token we had by doing test points on the good and then our product. Unfortunately, it still functioned the same as it had before the part was removed. So, I went back to remove the next component from the left- the RGB LED. This LED isn’t the same as the one we were supposed to get, as the part had run out, but supposedly it’s similar. However, when looking at reviews online, we saw that people had a lot of moisture problems with it. So, this could very well be why we’re having problems. However, the LED is even harder to desolder than the switch was. It’s leads are very close together and almost entirely under the component. This means that you can’t suck out any solder with solder wick because you can’t even see the pads. So for now the LED is just a work in progress.